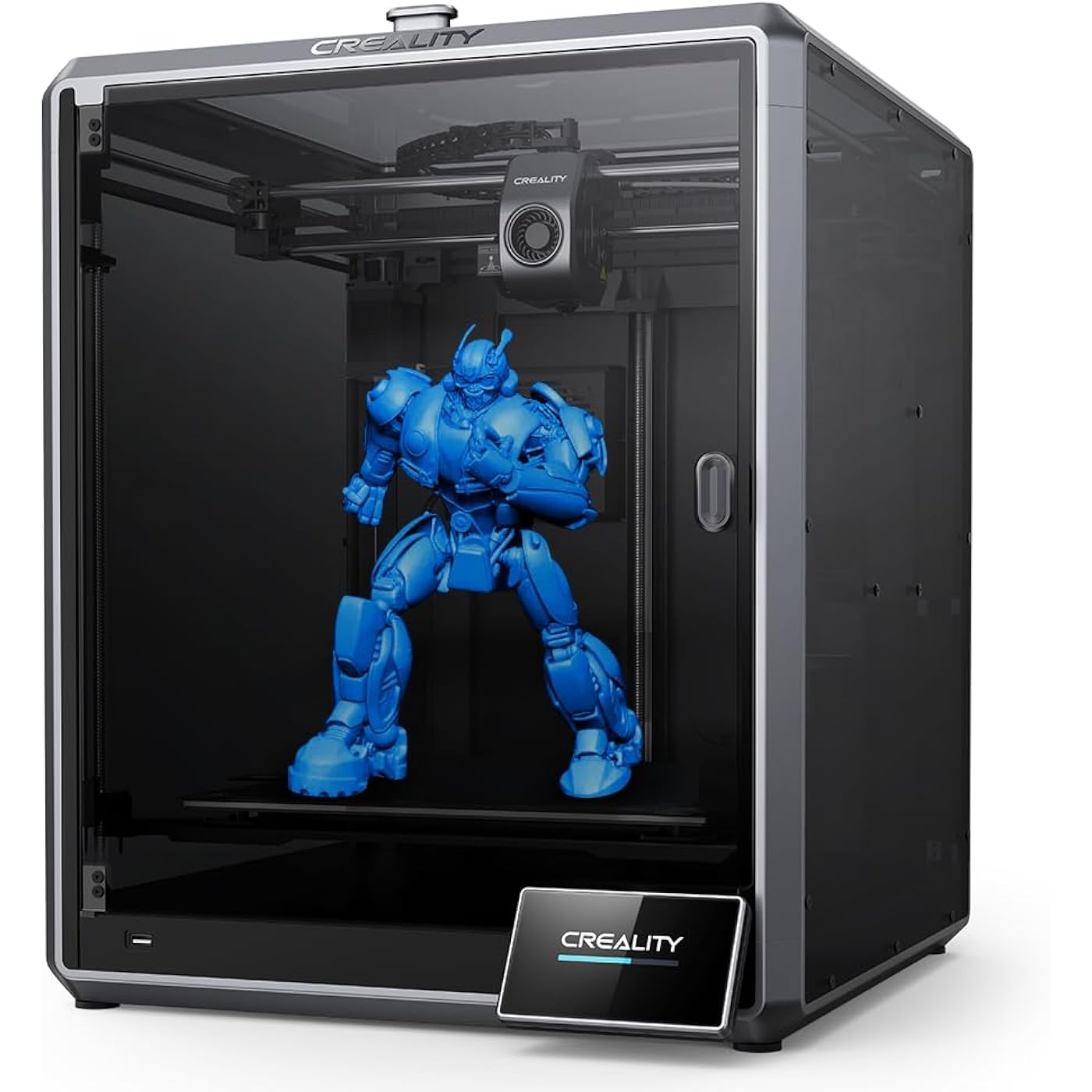

Creality K1 Max 3D Printer with Smart AI Function 600mm/s Printing Speed 20000mm/s² Acceleration, Core XY Structure 11.81x11.81x11.81 inch Large Build Volume Auto Leveling Dual-Gear Extruder

Buy Now, Pay Later

- – Up to 36-month term if approved

- – No impact on credit

- – Instant approval decision

- – Secure and straightforward checkout

Ready to go? Add this product to your cart and select a plan during checkout.

Payment plans are offered through our trusted finance partners Klarna, Affirm, Afterpay, Apple Pay, and PayTomorrow. No-credit-needed leasing options through Acima may also be available at checkout.

Learn more about financing & leasing here.

Selected Option

30-day refund / replacement

To qualify for a full refund, items must be returned in their original, unused condition. If an item is returned in a used, damaged, or materially different state, you may be granted a partial refund.

To initiate a return, please visit our Returns Center.

View our full returns policy here.

Recently Viewed

Model: K1 Max

Features

- Smart AI Function: Creality K1 Max equips 1 Micrometer Resolution AI Lidar, which scans the first layer, if there is any problem, it will stop the printing job giving you quality models. Observant AI Camera can recognize spaghetti failure, foreign matter, debris, etc. and support real-time monitoring and time-lapse filming

- 12 Faster and More Efficient: Creality K1 Max 3d printer, equips printing speed 600 millimeter per second and acceleration 20000 millimeters per square second, it is12 times faster than the other normal 3d printer. Give good printing experience to customers and get a good model in short time

- Size-efficient with Max Capacity: K1 Max offers a 11.81x11.81x11.81 inch large build volume, which meets more requirement of larger printing model, or you can get a print farm on this printer

- Dual Hands-free Auto Leveling: Creality K1 Max 3d printer, its strain sensors in the heatbed for more precise auto leveling without any operation or attention

- More Efficient Function: Core XY Structure of K1 Max makes the printing more stable. Prompt model cooling by a fan on the printhead with directional air ducts and also an auxiliary fan in the build chamber.

Brand: Comgrow

Material: Glass and Metal

Color: white

Product Dimensions: 17.12"D x 18.18"W x 20.7"H

Item Weight: 39.68 Pounds

Product Dimensions: 17.12 x 18.18 x 20.7 inches

Item Weight: 39.7 pounds

Item model number: K1 Max

Date First Available: August 31, 2023

Manufacturer: Creality 3D

Frequently asked questions

To initiate a return, please visit our Returns Center.

View our full returns policy here.

- Klarna Financing

- Affirm Pay in 4

- Affirm Financing

- Afterpay Financing

- PayTomorrow Financing

- Financing through Apple Pay

Learn more about financing & leasing here.

Similar Products

Top Amazon Reviews