Ready to go? Add this product to your cart and select a plan during checkout. Payment plans are offered through our trusted finance partners Klarna, PayTomorrow, Affirm, Afterpay, Apple Pay, and PayPal. No-credit-needed leasing options through Acima may also be available at checkout.

Learn more about financing & leasing here.

30-day refund/replacement

To qualify for a full refund, items must be returned in their original, unused condition. If an item is returned in a used, damaged, or materially different state, you may be granted a partial refund.

To initiate a return, please visit our Returns Center.

View our full returns policy here.

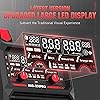

Style: MIG-250PRO

Features

Manufacturer: YESWELDER

Part Number: MIG-250PRO-AL

Item Weight: 33 pounds

Package Dimensions: 21 x 15.9 x 13.5 inches

Item model number: MIG-250 PRO

Size: MIG-250PRO

Style: MIG-250PRO

Material: Metal

Voltage: 220 Volts

Item Package Quantity: 1

Batteries Included?: No

Batteries Required?: No

Date First Available: July 3, 2020