Lunyee 3018 Pro Ultra CNC Machine 500W All-Metal CNC Router Machine, Upgraded 3 Axis Engraver Machine Limit Switches & Emergency-Stop with GRBL Offline Control for Metal, Wood, Acrylic, PCB MDF

Buy Now, Pay Later

- – Up to 36-month term if approved

- – No impact on credit

- – Instant approval decision

- – Secure and straightforward checkout

Ready to go? Add this product to your cart and select a plan during checkout.

Payment plans are offered through our trusted finance partners Klarna, Affirm, Afterpay, Apple Pay, and PayTomorrow. No-credit-needed leasing options through Acima may also be available at checkout.

Learn more about financing & leasing here.

Selected Option

FREE refund/replacement until Jan 31, 2026 Learn more

To qualify for a full refund, items must be returned in their original, unused condition. If an item is returned in a used, damaged, or materially different state, you may be granted a partial refund.

To initiate a return, please visit our Returns Center.

View our full returns policy here.

Style: 3018 pro ultra

Features

- New Upgrade: Based on Z-Axis Height of 80mm and 500w Spindle, The X-Axis is Upgraded to HGH15 Linear Guide. These New Upgrades Make Metal Engraving Easier and are Very Suitable for Unlimited Drilling and Engraving Operations on Various Metals. Such as Brass, Copper and 6061 Aluminum, Etc.

- High Precision: Building Upon the Foundation of 3018 Pro Max, The Upgraded Linear Guide Structure 2040 X-Axis Profiles and 4040 Y-Axis Profiles Significantly Enhance Engraving Accuracy and Processing Strength. This Enhancement Resolves the Z-Axis Instability Issue Common in Most Other Desktop CNC Machines.

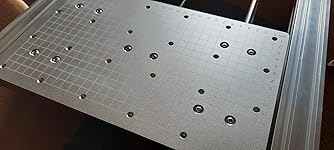

- Scale Grid Aluminum Plate Platform: The One-Piece Machined and Molded Aluminum Design Ensures the Flatness and Strength of the Work Platform. The Integrated Measurement Scale Provides Convenience for Material Positioning. Additionally, We Upgraded 2pc T-Track Mini Hold Down Clamp Kit in The Box, It can Provide You with a Heavy Duty and Reliable Solution.

- Integrated Switching Power Supply Design: In Order to Improve the Efficiency of Installation, 3018 cnc Pro Ultra Has Upgraded the Power Supply and Adopted an Integrated Power Supply Design, Which Greatly Reduces Wiring Time and Improves Safety. The New Upgrade Highlights Professionalism Everywhere.

- Easy Assembly and Great Support: 3018 Cnc Pro Ultra have Pre-Assembled Main Parts and Clear Cable Management. Assembly Videos and Paper User Manuals are Provided. Contact Us for any Queries, and Our Support Team Will Respond Within 24 Hours.

- Auxiliary instructions: We provide Machine Installation and Wiring Videos. Please Watch Them on the Product Link Page. The Package Contains a 4G USB Flash Drive and the Relevant Software has been Pre-installed.

Brand: LUNYEE

Material: Aluminum

Power Source: ac/dc

Voltage: 110 Volts

Item Weight: 14 Kilograms

Brand: LUNYEE

Material: Aluminum

Power Source: ac/dc

Voltage: 110 Volts

Item Weight: 14 Kilograms

Horsepower: 500 Watts

Maximum Rotational Speed: 12000 RPM

Base Type: Fixed

Battery Description: Corded electric

Manufacturer: LUNYEE

Part Number: 3018 pro ultra

Item Weight: 30.8 pounds

Package Dimensions: 20.7 x 18.2 x 11.9 inches

Item model number: 3018 pro ultra

Style: 3018 pro ultra

Wattage: 500 watts

Batteries Included?: No

Batteries Required?: No

Description Pile: Corded electric

Date First Available: September 8, 2023

Frequently asked questions

To initiate a return, please visit our Returns Center.

View our full returns policy here.

- Klarna Financing

- Affirm Pay in 4

- Affirm Financing

- Afterpay Financing

- PayTomorrow Financing

- Financing through Apple Pay

Learn more about financing & leasing here.

Similar Products

Top Amazon Reviews